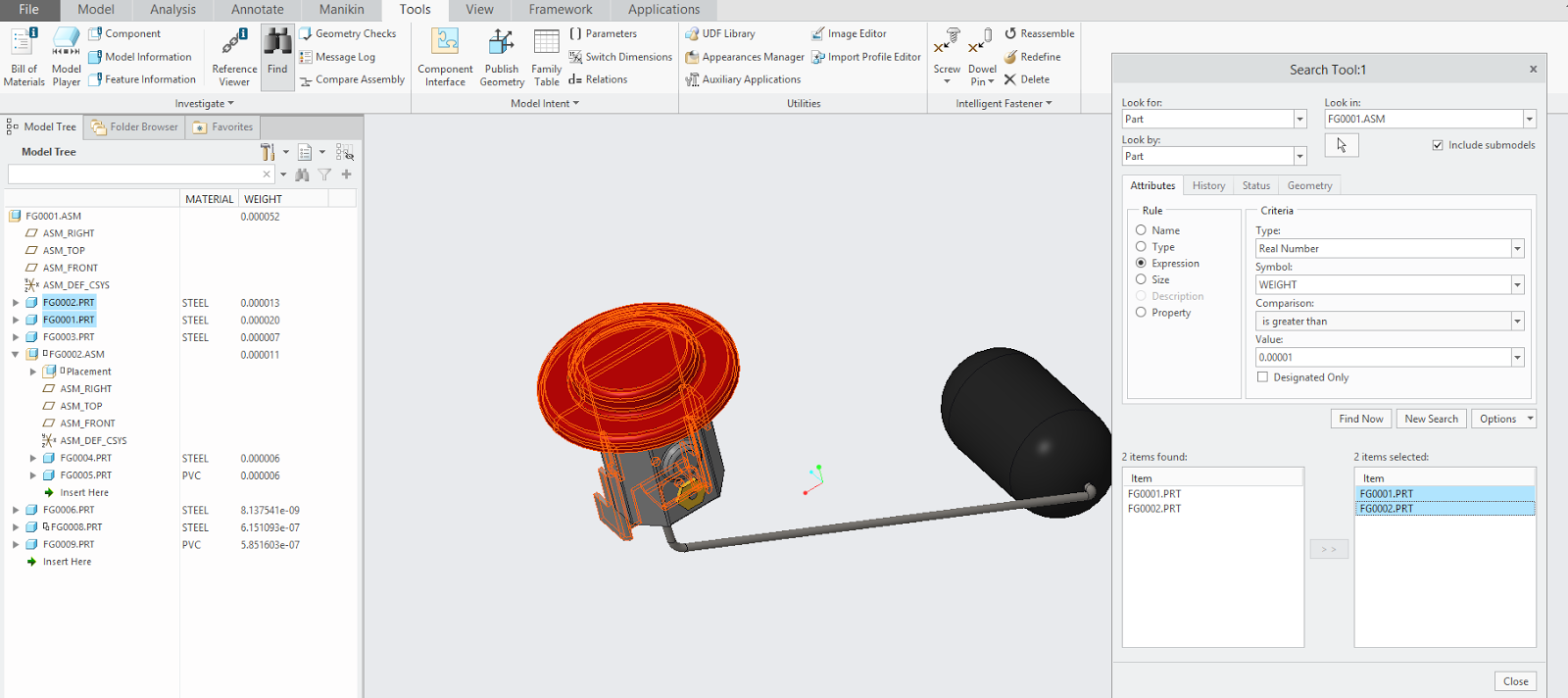

DS18B20 water

proof temperature sensors hooked up to Arduino UNO

I am not an electronics guy. I am a mechanical engineer and

as a part of personal project, I had to record temperatures from three

different heat sources. Let me jump right into the procedures showing how the

sensors are hooked up to Arduino and make them work.

Hardware

requirements

1.

Arduino Uno

2.

A bunch of jumper wires

3.

Resistor- 4.7 KΩ

4.

Bread Board

5.

Temperature sensors – 3 quantity

6.

USB- cable for Arduino

Software

Requirement

Arduino programme

Circuit Diagram

Sensor wire Colour

indication

Some cases you may find a yellow colour instead of Blue. Nevertheless,

they serve the same purpose.

Pull-up Resistor

I did not have a single 4.7KΩ, I used two 10 KΩ in parallel,

producing an effective 5KΩ.

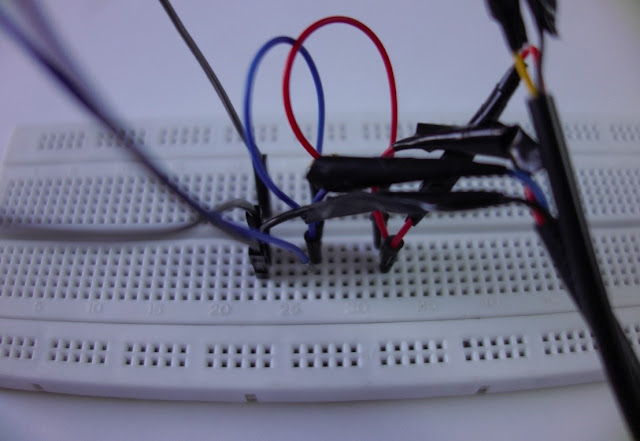

Build Bread board

circuit

Following images show the steps. Connect the jumper wires as

shown from step1 through step4.

1.

2.

3.

4.

1. Sensor-1 connected

2. Sensor-2 connected

Sensor-3 connected

Connect wires from Bread Board to Arduino as shown below

Orange wire goes to +5V on Arduino board

Black goes to –GND on Arduino board

Blue goes to Digital connector number - 2 here

Now connect Arduino to computer using the USB cable.

Uploading the sketch gives the following output on Serial Monitor

Arduino sketch is given below for 3 sensors; header files are also included.

Downloads :

Feel free to contact me in case of questions